Every millimeter off-line at layout becomes a meter of rework down the road. And in construction, mining, or infrastructure builds (where deadlines don’t move and budgets don’t flex), survey errors cost real money. Studies show rework can eat up 5% to 20% of a project’s total value, much of it tied to inaccurate layout and poor data capture.

Since 1999, Harper Surveying has paired field-tough GNSS gear with hands-on support, helping crews hit specs the first time.

We understand what keeps a fix under the canopy. We know how to help a crew move through dead zones. We also know what to do when your gear fails during a survey.

This guide explains how to choose the best GPS survey equipment for your site, workflow, and crew. It avoids confusing specs and sales jargon.

Why Accuracy in GPS Surveying Pays for Itself

Accuracy is the quiet moneymaker on every site.

Protects Profit Margin

More than half of project cost overruns come down to bad data and miscommunication. Precise coordinates from the start keep those overruns off the books.

Buys Time

Crews using RTK-enabled GPS survey equipment finish stake-out up to 20% faster. Tilt compensation and live corrections help remove delays in rod leveling. Faster layout means machines start grading sooner and rental gear goes back early.

Lowers Risk

Multi-band GNSS receivers perform better in tree-covered and high-reflection zones, tightening variance before inspectors ever arrive.

Powers the Workflow

Modern rovers stream verified data straight into BIM models, machine control, and as-built reports. That shared, centimeter-grade backbone keeps engineers, operators, and auditors working from a single truth.

What this all means is you pay once for precision, and earn it back in dollars saved, days gained, and headaches dodged.

Key Factors When Selecting GPS Survey Equipment

Not all GPS land survey equipment is built for the realities of the field. Some hold signal through canopy and urban canyon environments. Some lose lock when the weather shifts. These are the factors that separate what works from what works against you.

Accuracy & Precision

If your gear can’t be fixed fast or hold under interference, it doesn’t belong on a jobsite. Multi-band GNSS that tracks all major constellations (GPS, GLONASS, Galileo, BeiDou) is now the standard. It’s how your crew stays locked in and on track.

Durability & Field Readiness

GPS surveying equipment gets dropped, soaked, and baked. This makes IP67+ housing, vibration resistance, and solid temp tolerance field requirements. If your receiver shuts down in a cold snap, it’s dead weight.

Ease of Use

Interfaces should get out of the way. Look for receivers that connect fast, pair with your software stack, and let your crew get to work without a 30-page manual. Some crews train in-house, and some don’t. Your gear should flex either way.

Battery Life and Power Management

Stake-out days run long. Your GPS survey equipment should, too. You want at least 10 hours of runtime in the field (more if you’re doubling shifts). Hot-swappable batteries, clean charge status, and USB-C help keep downtime off the schedule.

Connectivity and Data Transfer

Your GPS surveying equipment gear needs to talk—clearly and consistently. That means stable Bluetooth, reliable Wi-Fi, and cellular or UHF options for RTK corrections. On remote builds, a dropped signal doesn’t just delay work—it can reset the day.

Cost-to-Value Balance

Lower-cost receivers that burn hours or lose data will pay you back in overtime, not output. Look at service history, firmware stability, and how well it integrates with your existing systems.

Support and Warranty

The real test isn’t the first setup. Instead, it’s the first failure. Choose a supplier who picks up the phone, ships fast, and knows how to troubleshoot the gear they sell. If you’re on the clock, they should be, too.

Top-Rated GPS Survey Equipment: 5 Field-Proven Units

No shortage of GPS survey equipment exists, but only a few units earn their keep on jobsites. These five receivers are field-tested, crew-approved, and proven to outperform when accuracy and uptime matter most.

1. Reach RS2+ Multi-Band RTK GNSS Receiver

The RS2+ stands out as a reliable rover for solo crews and compact sites. Its quick fix time, multi-band accuracy, and long battery life make it great for fast turnarounds and daily use. While it doesn’t cater to enterprise-scale survey teams, it meets the core needs with solid field consistency.

Pros

- Tracks GPS, GLONASS, Galileo, BeiDou (L1/L2/L5)

- 16 hours RTK use, and 22 hours logging

- 8km LoRa baseline

- Lightweight, USB-C charging

- Pairs easily with Emlid Flow

Cons

- Fewer accessories than premium units

- Less suited to multi-crew or high-volume workflows

2. Carlson BRx7 RTK GNSS Receiver

The manufacturer designs the BRx7 GPS land survey equipment for teams working in different conditions, like steel and trees. It combines strong multi-constellation tracking with Carlson’s workflow tools. SureFix delivers clean vectors even when satellites drop, and the 12-hour battery set swaps fast if your day runs long.

The BRx7 is not a lightweight rover. However, it is perfect for tough sites where downtime costs a lot. It gives up some weight for reliable uptime and strong data integrity.

Pros

- Dual-frequency RTK with SureFix processing

- Holds signal in canopy and urban reflections

- Rugged IP67 housing

- Tight integration with SurvCE/SurvPC and Carlson layout tools

- Hot-swappable batteries, with up to 12 hours of runtime

Cons

- Higher price bracket

- Bulkier than compact rovers

3. Leica Viva GS16

The GS16 is built for crews who bounce between wide-open cuts and steel-cluttered city blocks. Its RTKplus engine grabs a fix fast, then defends it when satellites fade.

SmartLink fills the gap if network RTK cuts out, so you stay productive on remote or congested jobs. Each Li-ion pack runs for about eight hours and can be swapped without requiring a reboot. If your team wants to invest in high-quality precision, consider the Leica system. The GS16 is very reliable.

Pros

- RTKplus engine with 555-channel, multi-frequency tracking

- Self-learning algorithm adapts to canopy and urban interference

- SmartLink satellite corrections keep fixes when cell service drops

- IP68 and MIL-STD ruggedness

Cons

- Premium price tag

- Steeper learning curve for crews new to Leica Captivate

4. Hemisphere S631 GNSS Smart Antenna

Field crews like the S631 for its blend of portability and signal toughness. Athena grabs centimeter fixes fast, while Atlas keeps you in the game when cell or UHF links drop.

The web interface is helpful for teams with different devices. Any phone or tablet can change settings without a special controller.

The S631 may not match high-end units in terms of complex software systems. However, it is a great choice when you need a portable rover. It offers RTK and PPP features right out of the box.

Pros

- Athena RTK engine with multi-constellation, multi-frequency tracking

- Atlas® L-band service for sub-decimeter accuracy without a base

- Lightweight and compact for rover work

- Dual hot-swap batteries (about 12 hours combined) keep surveys rolling

- WebUI lets crews configure or troubleshoot from any browser

Cons

- Interface isn’t as intuitive as top-tier rivals

- Limited third-party accessory ecosystem

5. Sokkia GRX3 GNSS Receiver

The GRX3 is built for crews who value consistency over flash. It tracks satellites effectively and maintains a fix in light cover. Its tilt sensor helps speed up work on uneven ground, especially during topographic work in earthworks.

The GRX3 may not be as fast as newer GNSS cores. However, it is a strong choice when you need a tough rover. It works well with MAGNET workflows and continues to operate smoothly shift after shift.

Pros

- 226-channel GNSS engine; supports GPS, GLONASS, Galileo, BeiDou

- Tilt compensation up to 15 inches for slope and offset shots

- IP67-rated, drop-tested for jobsite abuse

- 12-hour hot-swappable internal battery

- Integrates cleanly with MAGNET Field and Sokkia controllers

Cons

- No onboard LTE, so it needs an external modem or controller hotspot

- Slower fix times than newer tri-band receivers

Match the Right GPS Surveying Equipment Unit to Your Industry

Every crew faces different terrain, tolerances, and workflows. Here’s where each receiver delivers most.

Vertical Construction: Carlson BRx7 or Leica GS16

Strong under canopy, solid signal lock near steel, and fast integration with layout and machine control tools.

Mining and Exploration: Leica GS16 or Hemisphere S631

Adapts to shifting terrain. RTKplus and Atlas™ handle pit expansion and loss of cell coverage.

Manufacturing and Scrap Yards: Reach RS2+ or Sokkia GRX3

Their compact form factors and tilt shots speed layout in cluttered yards without busting budgets.

Environmental & Civil Surveys: Reach RS2+ or Hemisphere S631

Lightweight, easy to deploy, and accurate even in partial cover—ideal for sensitive zones and compliance surveys.

Tips for Maximizing Accuracy in the Field

Even the best survey GPS equipment loses value if it’s poorly set up or out of sync with the jobsite. Here’s how to lock in performance:

- Calibrate before first shot: Always level the pole, zero the tilt, and verify the coordinate system. A five-minute check beats hours of rework.

- Watch the sky: Multi-band GNSS handles partial cover, but full canopy or reflective glass still needs line-of-sight awareness.

- Research existing control: Verify local control points against known benchmarks. Bad control is the fastest way to misaligned layouts.

- Stay updated: Keep firmware current. Often on a monthly basis, manufacturers push signal tracking, battery tuning, and bug fixes.

- Don’t skip field checks: Spot-check with known points during the day because drift happens.

Set up right, GPS surveying equipment anchors your entire build to a single source of truth.

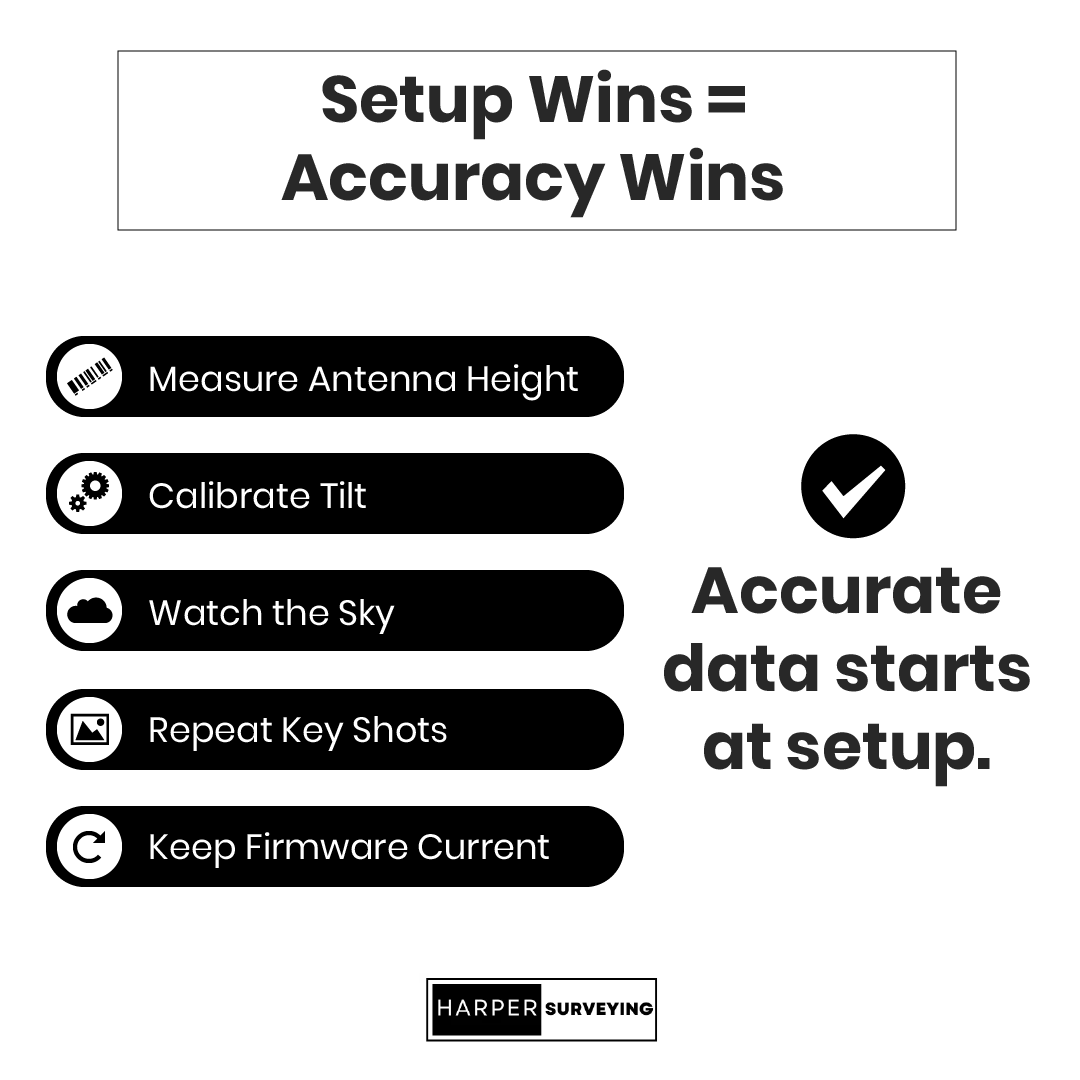

Include five steps (top to bottom)

1. Measure Antenna Height

2. Calibrate Tilt

3. Watch the Sky

4. Repeat Key Shots

5. Keep Firmware Current

For the footer, use a small Harper logo and add this line: “Accurate data starts at setup.”

Harper Surveying: GPS Survey Equipment with Expert Support

When time is money, support matters as much as specs. Harper Surveying pairs every piece of GPS survey equipment with:

- Practical guidance, on demand. Live phone help during business hours and 24/7 online support from technicians who know the gear inside out.

- Same-day processing. In-stock receivers ship fast, so downtime stays off the schedule.

- Transparent pricing and solid warranties. Pro-grade gear, clear numbers, no surprise extras.

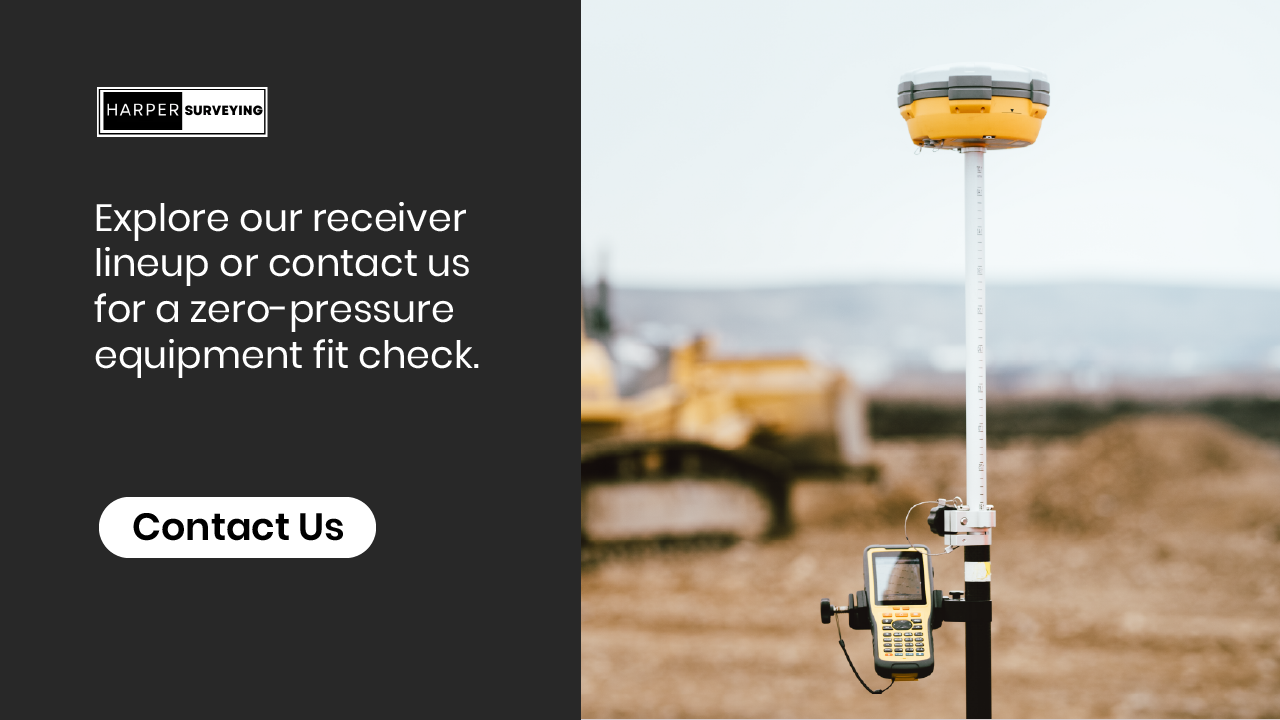

Ready to swap guesswork for guaranteed accuracy?

Explore our receiver lineup or contact us for a zero-pressure equipment fit check.