Construction teams lose 35% of their time to non-optimal work, about $177.5 billion in U.S. labor each year. On-site, that can mean an afternoon lost re-establishing control after a base station drops. The fix starts with fit—gear matched to your tolerances, site, and crew.

In this guide, we’ll show you how to invest where precision pays and keep the rest lean. You’ll define your needs and choose surveying equipment that protects the schedule and your surveying equipment budget.

Why Cost vs. Quality Matters in Surveying Equipment

Globally, 14% of all construction rework is caused by bad data—about $88.69 billion in avoidable cost. Additionally, on a typical project, direct rework averages 4 to 6% of total cost, and can reach about 9% once indirect impacts are counted.

Here’s how those numbers turn into invoices. Two centimeters off at layout can bake into a steel order and move anchor bolts. When it shows up, you’re already into change orders.

Hidden costs to account for before you buy:

- Calibration and verification cycles that pull gear from the field

- Software renewals or unexpected license migrations

- Training time before crews hit productivity targets

- Service turnaround and parts availability

- Controller and software compatibility checks

- Data storage and processing for large scan sets

Treat these as part of the total cost of ownership.

Understanding Your Needs

Buying surveying equipment without locking down your constraints first is an easy way to overspend, or worse, mis-spec and stall the job.

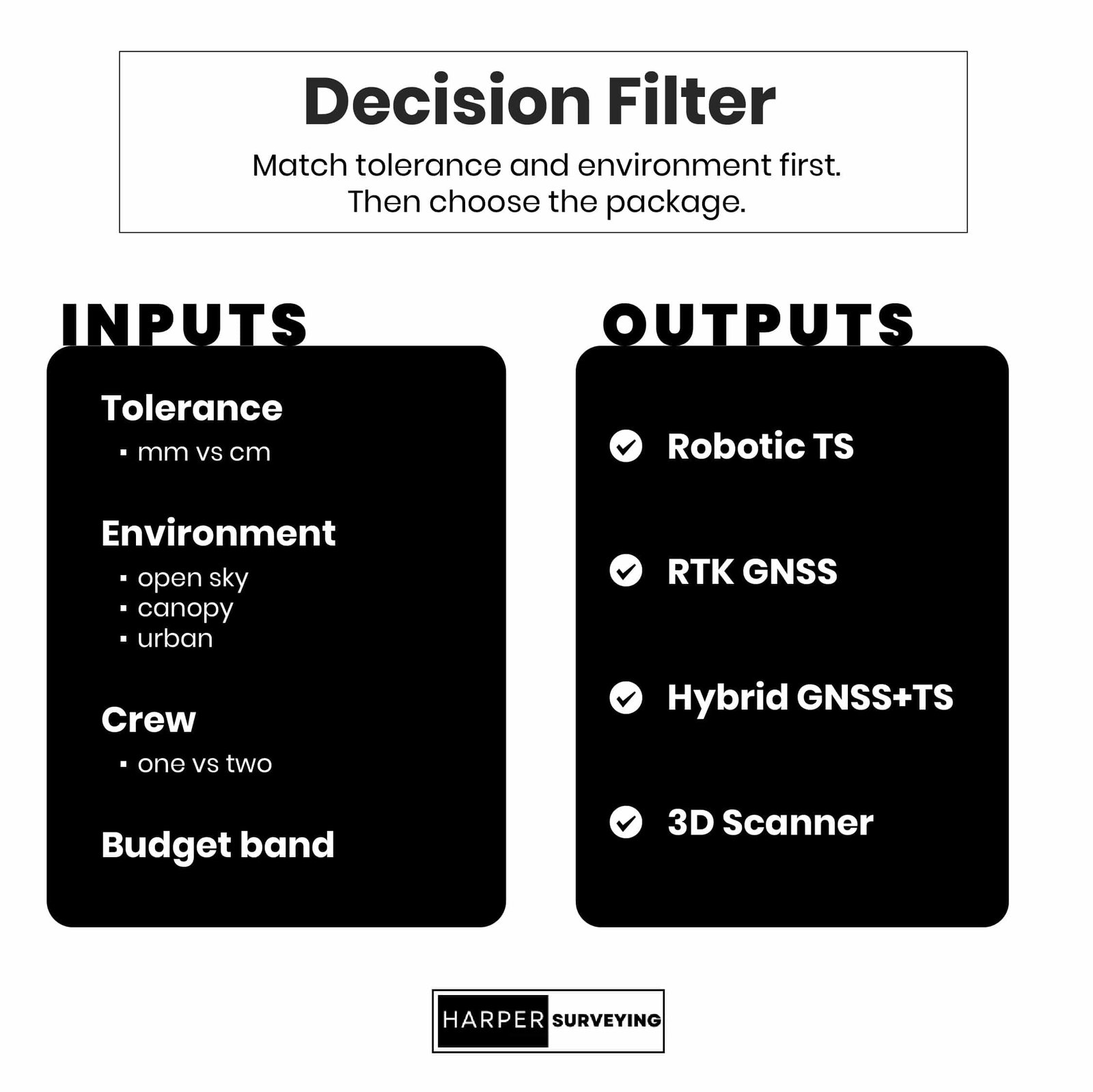

Once you’ve set your tolerances, site conditions, workflow, and budget, the right package will stand out and the wrong ones will drop away.

Define Project Scope

Start with the deliverable. A topographic survey needs different precision than anchor bolt layout or deformation monitoring. Boundary retracement, as-builts, machine control guidance, and structural checks each need a defined accuracy class.

Map your needs to realistic classes.

- For setting out grids and position points, ISO 4463 supports millimeter-level targets, which is about ±3–4 mm over short runs.

- For construction staking, plan for centimeter-level results: around ±15 mm for finish or subgrade stakes and about ±30 mm for excavation or embankments, with rough grading looser.

- For topographic mapping deliverables, align to ASPRS vertical accuracy classes. For example, 10 cm RMSEz for 1-ft contours.

Choosing surveying equipment far beyond the accuracy your work requires will raise costs without improving the outcome.

Assess Site Conditions

Sky view and signal environment dictate how your instruments will perform.

Open terrain gives GNSS receivers a clear edge. Canopy, reflective surfaces, and corridors cause multipath and GNSS dropouts. In those cases, robotic total stations or scanners, which don’t rely solely on satellite fixes, may offer better accuracy.

Factor in environmental stresses. High dust loads, vibration from adjacent equipment, as well as freeze–thaw cycles require an ingress protection (IP) rating and operating temperature range proven for those conditions:

- IP65 blocks dust and resists low-pressure water jets.

- IP67 blocks dust and withstands brief submersion.

Timeline and Workflow Requirements

Match instrument capability to crew setup and schedule. Robotic total stations support single-operator work.

If speed is critical, RTK-grade GNSS or hybrid setups deliver real-time centimeter stakeout and checks, enabling leaner, single-operator workflows on suitable sites.

Consider post-processing requirements. Laser scanners with automated pre-registration and BIM integration can reduce time spent in the office, but only if your hardware and software can handle large data sets without bottlenecks.

Budget Parameters

How you finance your land surveying equipment can be as critical as what you buy.

Buying (CapEx):

- Full control over maintenance schedules and upgrades.

- Best when use is high year-round and you can maintain calibration in-house.

Leasing (OpEx):

- Matches costs to variable workloads or rapid tech cycles.

- Limits upfront spend but requires tight control over return conditions and service terms.

Price is driven by accuracy class, onboard sensors, controller type, field or office software licenses, and service plan coverage—each affecting both upfront and lifecycle cost. Weigh each factor against your schedule and tolerances.

Factors for Selecting a Surveying Package

Now, pressure-test each option against those constraints.

Accuracy and Precision

Confirm the instrument holds your required accuracy under real conditions. Use ISO 17123 field procedures for total stations, GNSS, or levels, and compare results to your requirements.

If a receiver drops fix under canopy or a total station drifts in heat, expect rework and delays.

Durability and Environmental Fit

You also want to validate durability on site. An IP67 label means little if you incur repair costs from sustained vibration and fine dust. Ask for references in similar environments or run a short trial before you commit.

Ease of Use and Training Impact

The best land surveying equipment for you fits your crew without slowing the job.

- Controller layouts that put core functions within thumb reach.

- Guided workflows and tilt compensation speed onboarding and repetitive stakeout.

Support and Warranty

Score vendors based on repair turnaround, local parts availability, and regional calibration options.

If you rely on this gear daily, a two-week wait is two weeks of missed production.

Need a vendor-neutral field trial or bundle planning aligned to your tolerances? We can stage it and handle calibration and training.

Software Ecosystem and Data Flow

Your surveying equipment should move data through your field-to-office pipeline without conversions.

Test it with your current stack (Trimble Access with TBC, Leica Captivate with Cyclone, or Topcon MAGNET with Pocket3D) so deliverables land cleanly.

Scalability and Future-Proofing

Choose hardware that grows with you. Modular sensors and firmware unlocks extend service life. Many platforms use annual subscriptions. Plan renewals so year-two costs don’t catch you off guard.

Top 5 Surveying Packages: Features, Pros & Cons

1. Trimble S5 Robotic Total Station: Best for Lean Crews

Why Trimble S5 works

Motor drive and SurePoint keep the line steady. A single operator can stake fast without chasing drift.

Pros

- DR Plus measures quickly on mixed faces.

- Trimble Access with TBC seamlessly transfers data to the office.

Trade-offs

- Needs a matched controller and a short robotics ramp for new crews.

- Software subscriptions add to the total cost.

Price (ballpark): About $40K for the instrument. Controller and software are extra.

Spec anchor: Angle options 1″–5″.

Use the Trimble S5 when the line of sight is clear and millimeter-level layout accuracy is required.

2. Leica Viva TS16: Best for Dynamic Locking

Why Leica TS16 works

ATRplus tracks through foot traffic. DynamicLock quickly re-acquires when someone cuts your line.

Pros

- PowerSearch finds prisms fast in clutter.

- Captivate’s interface speeds 3D checks in the field.

Trade-offs

- Steeper learning curve for teams new to Leica.

- Service costs can trend higher.

Spec anchor: Angular accuracy options down to approximately 1″.

Choose Leica Viva TS16 when congested jobs demand strong target lock and reach.

3. Topcon GT605 (GT-600 Series): Best for General Construction Layout

Why GT605 works

Ultrasonic motors track smoothly. IP65 ensures it withstands dust and spray.

Pros

- One-person efficiency with MAGNET or Pocket3D.

- Series accuracy options match tolerance and spend.

Trade-offs

- Needs a compatible controller for full capability.

- The reflectorless range varies with the target and the light.

Price (ballpark): About $30K.

Spec anchor: 5″ angular accuracy.

Use GT605 for earthwork, rough grading, and structural layout where ±15 to 30 mm is acceptable.

4. Leica RTC360 3D Laser Scanner: Best for Rapid, Registration-Ready As-Builts

Why RTC360 works

Full-dome capture in under two minutes. VIS pre-registration stitches scans on site and cuts office hours later.

Pros

- Up to 2 million points per second for dense models with low noise.

- Outputs color point clouds for context and clash review.

Trade-offs

- High CapEx.

- Large datasets require robust workstations and storage.

Price (ballpark): Approximately $ 80,000 for the scanner.

Use the Leica RTC360 when as-builts, MEP coordination, and clash-ready scans run on tight schedules, and the land survey equipment price must be weighed against the risk of rework.

5. Trimble R12i GNSS Receiver: Best for Fast Stakeout

Why Trimble R12i works

TIP tilt compensation allows you to shoot without needing to level the pole. The ProPoint engine helps keep a fix in a light canopy.

Pros

- Multi‑constellation tracking improves coverage and uptime.

- CenterPoint RTX extends reach when RTK isn’t available.

Trade-offs

- Limited in heavy canopy or urban canyons.

- Requires the full controller and software stack.

Price (ballpark): Costs around $30K+ for a complete system with controller and software.

Spec anchor: IP67 and sub-centimeter RTK class in open sky.

The Trimble R12i is a strong choice for GPS survey equipment, particularly for crews that balance speed with real-world positioning challenges.

Matching Equipment to Your Reality

Specs only matter if they fit your environment, crew, and tolerance demands. Use this as a quick filter before locking the budget:

- Dense urban sites: Robotic total station with dynamic lock for sub-5 mm layout accuracy.

- Open-sky earthwork: RTK GNSS for rapid stakeout at ±15 to 30 mm.

- Mixed canopy/corridors: Hybrid GNSS and total station for flexibility without re-setup.

- High-detail as-builts: 3D scanner with auto-registration for clash-ready models.

- Budget-limited builds: 5″ class total station where tolerances allow.

Maximize ROI on Surveying Equipment with Harper Surveying

Lease when use swings or tech turns fast. Buy when instruments are in use, and your team can keep calibration and firmware on schedule.

Before you sign, align scope and line items: controllers, software seats, batteries and chargers, tripods and rods, spares, a calibration plan, on-site training, priority service SLAs, and regional turnaround.

Harper Surveying builds a vendor-neutral shortlist and validates workflow on-site.

Explore Laser Scanners, GNSS Receivers, and Total Stations, or request a personalized quote to match the kit to risk and schedule.